Automated Wire Harness Assembly Services

S and Y Industries has dedicated customer-specific teams for performing automated wire harness assembly. Our state-of-the-art electronic manufacturing facility is automated to deliver precision quality and consistency with every custom wire harness, PCB component and turnkey box build that we deliver.

An Overview of Our Precision Wire Harness Assembly Equipment

At S and Y Industries, we tackle your low- to mid-volume wire harness manufacturing with superior automated production technology and unbeatable craftsmanship.

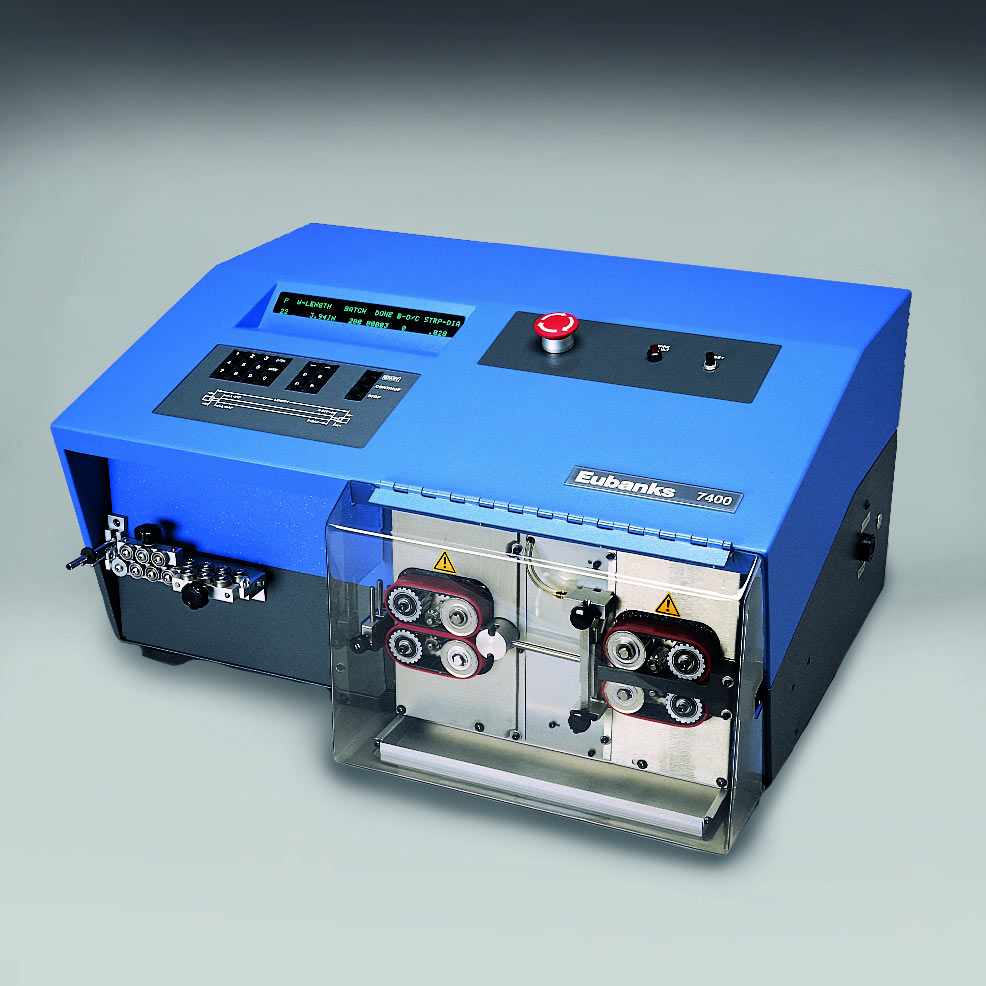

AutoStrip 7400

AutoStrip 7400

Our electronic assembly department utilizes Eubanks’ AutoStrip Model 7400 – a versatile wire processor machine capable of handling extremely long strip lengths. With a maximum wire length capacity of 1200”, the AutoStrip 7400 can cut-and-strip both ends at a rate of 500 pieces/hour for dual wire applications. If your custom wire harnesses require shorter 4” length wires, the AutoStrip 7400 can accommodate your production at a breakneck cut-and-strip speed of 8,200 pieces/hour.

Additionally, this advanced wire processor can handle gauges up to 8 AWG (8.6mm) in diameter, while also handling multi-conductor and flat cable gauges up to 5/16″ (8mm) in diameter.

AMP-O-LECTRIC G II+ Terminating Machine

AMP-O-LECTRIC G II+ Terminating Machine

Another piece of vital equipment in S and Y’s automated wire harness production department, the Model G II+ is engineered to process wire gauges of increased diameters up to 5.5 AWG (16mm). This advanced terminating machine offers precision variable speeds, giving our technicians the flexibility they need to tackle your most challenging and complex custom wire harness applications.

Other standout features include toolless applicator changeover, manual crimp height adjustment and split-cycle operation.

Branson 2000Xt Ultrasonic Welder

Branson 2000Xt Ultrasonic Welder

Our automated electronic assembly department utilizes Branson’s cutting-edge 2000Xt welder to accommodate our precision welding requirements. It features advanced digital amplitude control to ensure weld consistency along with a wide-range ultrasonic splicing system that can handle wire splicing diameters from 0.35 to 32mm.

Additionally, quality is ensured through a vertical stacking design which prevents side splicing – one of the most common points of failure.

Branson 2032S Wire Splicer

Branson 2032S Wire Splicer

For custom wire harness production necessitating a full-range ultrasonic splicing system, S and Y Industries utilizes Branson’s 2032S wire splicer system. This precision splicing machine features automated welding operations by time, peak power or ground detection.

Other advanced production features include programmable starting ramp time, precise digital amplitude control with profiling and digital autotune with memory for fully automatic wire harness production.

Additional Custom Wire Harness Production Tools and Equipment

We also have around 100 different hand crimping tools for Deutsche, Amp, TE, Molex and Pico connectors. Our state-of-the-art electronic production line is integrated with the tools to support virtually any type of harness connector, giving us the ability to handle almost any custom wire harness prototype or production project.

Your Single-Source Contract Manufacturer for Custom Wire Harness Solutions

S and Y Industries has cost-effective, low- to mid-volume electronic manufacturing solutions for over 35 years. Our streamlined electronic turnkey production capabilities include automated wire harness assembly and precision PCBA services, all backed by an industry-leading quality control system engineered in accordance with the latest AS9100D / ISO 9001:2015 quality certifications.

With a continued focus on the needs of our customers and their unique industries, we have developed a diverse customer base consisting of long-term partnerships with many of the world’s leading electronic component providers since 1984.